Sheet Metal Gusset Design Guidelines

Sheet metal gusset design guidelines. The following guidelines are recommended for draft angles in injection molding. Bends should be toleranced plus or minus one-half degree at a location adjacent to the bends. Corner Radius for Notch 05 x Sheet Metal Thickness.

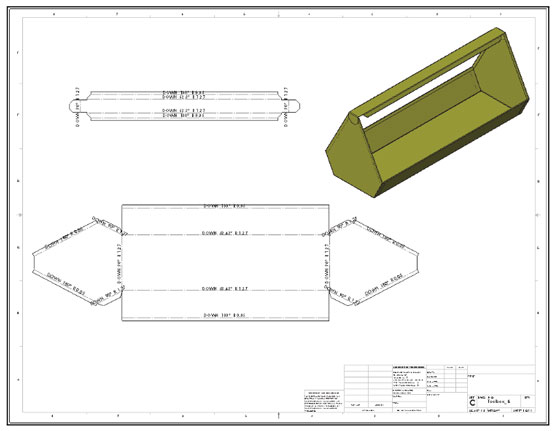

The method of pressing sheet metal also enables more complex geometries and thus makes it possible to eliminate welding of the components. Curls dimension outside radius must be at least twice the materials thickness. GLI Paris Projet ReAct.

Avoid large sheet metal parts with small bent flanges. For the ease of manufacturing multiple bends on the same plane should occur in the same direction. Larger quantities typically justify more sophisticated tooling.

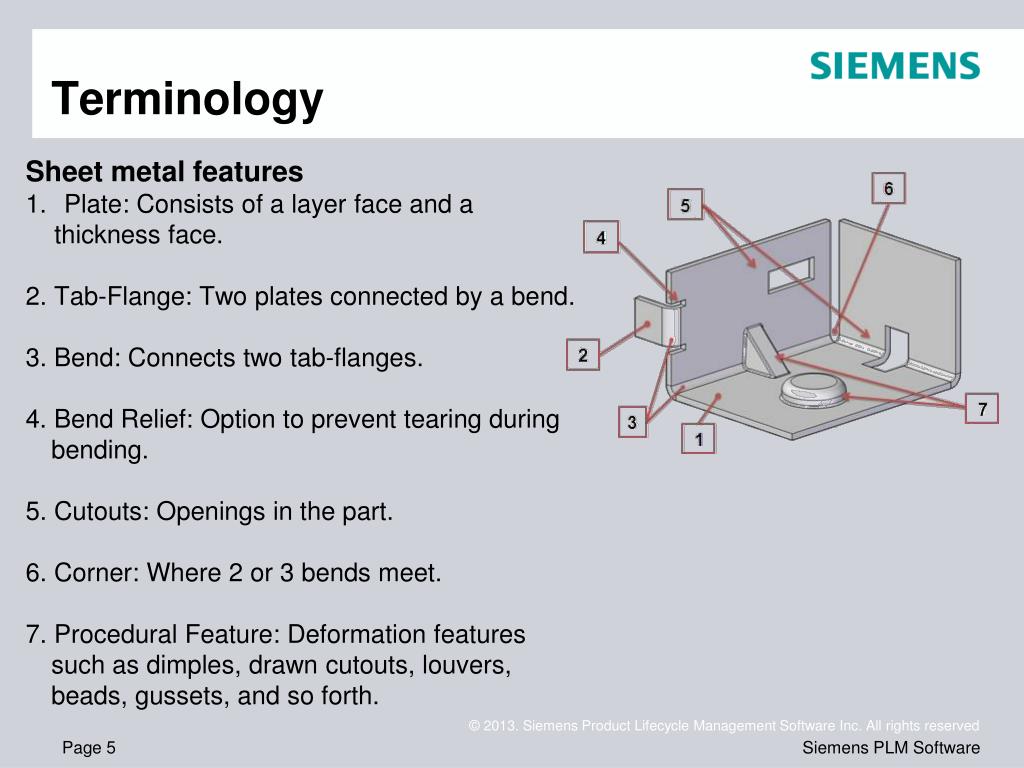

Bends can give strength and shape to a part and are formed in a machine using bend brakes. The flange length of a bend should be at least 3 times the sheet thickness. Engineering changes can be costly.

Recommended inside bend radius for sheet metal parts should be equal to material thickness. When Sheet metal parts have sharp corners try designing a fillet half of the material thickness. For the ease of manufacturing multiple bends on the same plane should occur in the same direction.

Here are some useful resources on sheet metal fabrication as well as other resources related manufacturing if you want to delve deeper. Keep draft angles at a minimum of 2 degrees. Search for jobs related to Sheet metal gusset design guidelines or hire on the worlds largest freelancing marketplace with 20m jobs.

In low carbon steel sheet metal the minimum radius of a bend should be one-half the. Bends in the same plane should be designed in the same direction.

Its free to sign up and bid on jobs.

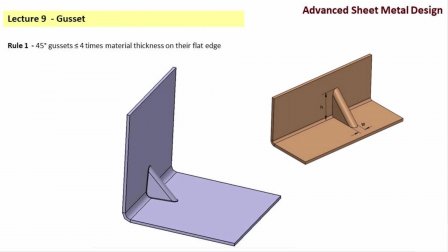

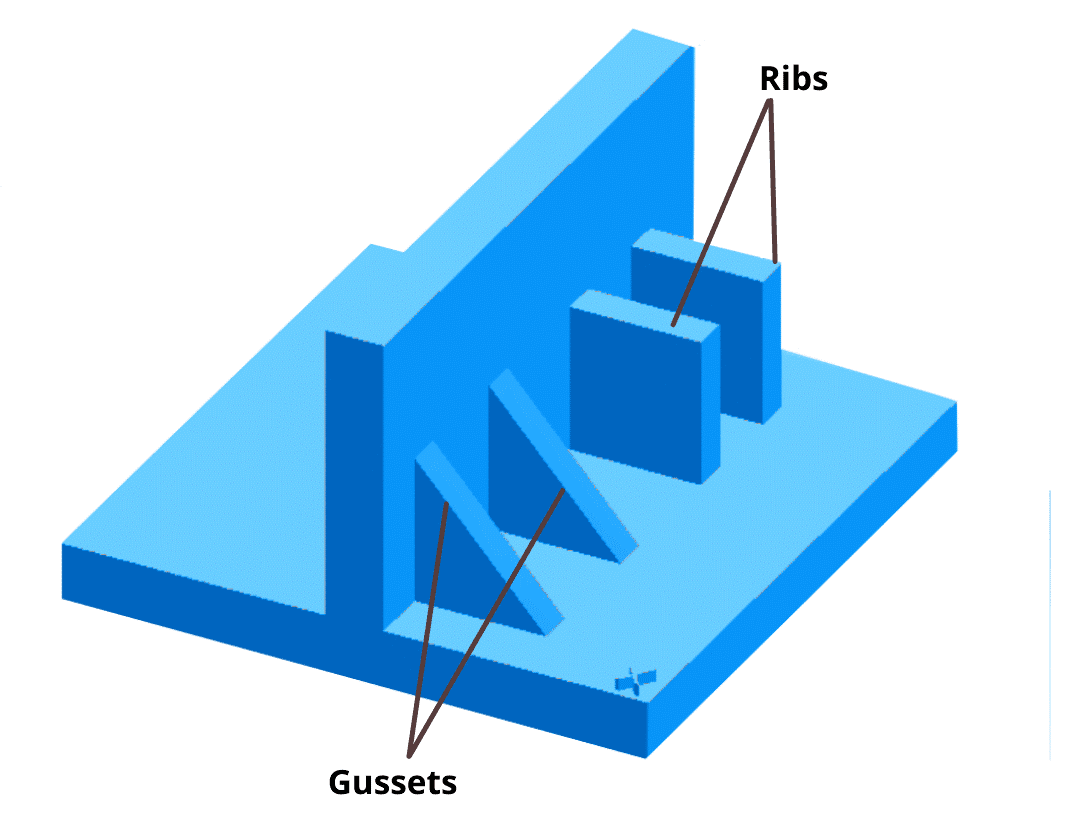

The following guidelines are recommended for draft angles in injection molding. Specific guidelines such as Minimum Distance from Hole to Gussets Minimum Distance from Extruded Holes to Part Edge Minimum Distance between Extruded Holes and Minimum Distance from Extruded Holes to Bend. Involve us during design stage to optimize cost and performance in component design. Avoid large sheet metal parts with small bent flanges. Here are some useful resources on sheet metal fabrication as well as other resources related manufacturing if you want to delve deeper. Since sheet metal cannot be bent to a 90-degree position without breaking at sharp corners all bends will have an acceptable bend radius. Bends in the same plane should be designed in the same direction. Keep draft angles at a minimum of 2 degrees. Engineering changes can be costly.

If you have tall features in your design you can enlarge the draft angles to up to 5 degrees. Since sheet metal cannot be bent to a 90-degree position without breaking at sharp corners all bends will have an acceptable bend radius. GLI Paris Projet ReAct. Specific guidelines such as Minimum Distance from Hole to Gussets Minimum Distance from Extruded Holes to Part Edge Minimum Distance between Extruded Holes and Minimum Distance from Extruded Holes to Bend. Oleh maselon Maret 18 2021 Posting Komentar Sheet Metal Gusset Design Guidelines - DesaignHandbags. Search for jobs related to Sheet metal gusset design guidelines or hire on the worlds largest freelancing marketplace with 20m jobs. Good sheet metal design goes beyond basic guidelines and considers the type of sheet metal fabrication process material finish fastening and tailors all these factors to the specific function.

Post a Comment for "Sheet Metal Gusset Design Guidelines"